Microprocessor Based Data Logger

Product Specification :

Model wise descriptions :

| Model | Description ( XX = No. of channels ) | Size in Horizontal &Vertical (w x h x d) mm |

| Datalog-16P-XX | Data Logger with parallel Printer port and 128KB of data storage and common High/Low alarms (XX = 04,08,12,16 channels) |

H-(192 x 96 x 200) V-(96 x 192 x 200) |

| Datalog-16PA-XX | Same as 8.1 but with per channel High/Low Alarm LED indication and transistor driver output to drive external relays (XX = 04,08,12,16 channels) |

H-(192 x 96 x 200) V-(96 x 192 x 200) |

| Datalog-16S-XX | Data Logger with RS-485/RS-232 Serial port and 128 KB of data storage and common alarms (XX = 04,08,12,16 channels) |

H-(192 x 96 x 200) V-(96 x 192 x 200) |

| Datalog-16SA-XX | Same as 8.2 but with per channel High/Low Alarm LED indication and transistor driver output to drive external relays (XX = 04,08,12,16 channels) |

H-(192 x 96 x 200) V-(96 x 192 x 200) |

| Note : Specifications are subject to change without notice � due to continuous upgradation. | ||

Description :

Libratherm offers Microprocessor based Sixteen Channel Temperature / Process Data Logger model DATALOG-16, which is most suitable for continuous monitoring and logging of temperature or process parameters at maximum 16 different locations. Each input has independent amplifier and hence each can be selected for different type of input. All the channels are displayed with the respective channel numbers. The front panel LED shows the Alarm status. For data logging of more than 16 channels more than one DATALOG-16 can be used. Single data logger can also be used for monitoring group of systems, each with variable number of process inputs with maximum eight groups. For example, 16 inputs may come from 4 furnaces each with 4 nos. of thermocouples. The data logging for each furnace can be done separately on single 16 channel data logger. The start and stop operation for each furnace can be initiated by 4 independent logic inputs.

Datalog-16 offers, built in data storage, common or individual high or low alarm set point with relay outputs, parallel Centronics interface and / or serial PC interface. The built in Real Time Clock allows real time data logging, parallel printer port allows on line and off line printing of the data on dot matrix printer and RS232/RS485 serial port allows data logging on to the PC. Required data acquisition software (DAS) operating on Windows (98, 2000, XP or Vista) is also offered for on line and off line viewing of all the channels on the computer screen in both graphical and tabular representation. Libratherm offers, standard and customized PC based software to meet user’s requirement.

Features :

• Available in standard ½ DIN sizes.

• Highly accurate and sturdy in operation.

• Accuracy better than ±0.1% of the full scale.

• Elegant looks, Very easy to operate.

• Accepts standard inputs like thermocouple, RTD - Pt-100 2 or 3-wire input, etc.

• Models with 4 to 16 inputs are available.

• High quality membrane keypad

• Power supply 230 VAC / 110 VAC ± 10%, 60 / 50 Hz

• PC compatible

| Design | Microprocessor based( 8 bit) with 12 bit ADC |

| No. Of channels | 4, 8, 12 or 16. |

| Input | Refer input and range selection table as given below. (each channel can be of same or different input type as per user’s requirement) |

| Accuracy | Better than ± 0.1oC, ± 1 oC / 0.1 or 1 UOM - Software Linearized. (Subject to specified input and range). |

| Resolution | 0.1oC, 1oC , 0.1 or 1 UOM (As per users requirement) |

| Display | 4 digits each 0.5" 7-segment red LED to display process and Alarm Set values. 2 digit 0.5" 7 segment red LED for channel number 6 digit 0.3" 7 segment red LED for real time clock and Calander. |

| Open Sensor/Input Indication | Display shows Flt-1 or Flt-2 and all outputs will be turned low. |

| Display Scan Rate | 1 to 99 sec (programmable through front panel keyboard) |

| Sampling Rate | 125mS (All 16 channels will be scanned in 2 seconds). |

| Skip/Hold Facility | Available through key board in configuration mode |

| Key board | 8 x 1 membrane keypad for data entry |

| Common Relay Outputs | 2 nos. potential free change over contact (1 each for high and low output but common for all the channels) |

| Individual Alarm Outputs | 2 per channel i.e. 32 open collector outputs to drive external relay cards. Alarms Can be configured for LL, HH, LH, HL) L – Low and H – High. |

| LED Indication | 32 LED's in the front indicating status of each alarm output |

| Data Logging | Real Time with Programmable log time and storage time |

| Serial / Parallel Interface | Parallel Centronics port (25 pin D connector) for 40 or 80 column dot-matrix printer. Serial (RS232 4 wire or RS485 2 wire )port on modbus ASCII protocol. USB interface can also be optionally provided. |

| Data Storage | Internal 128Kbyte memory bank (Static RAM) |

| Size (WxHxD) | 192 x 96 x 200 mm (DATLOG-16-H) or 96 x 192 x 200 mm. (DATALOG-16-V) |

| Panel Cutout | 186 x 92 mm., or 92 x 186 mm + 0.5 mm |

| Supply | 230VAC / 110 VAC ± 10% (10VA), 50/60Hz or 24VDC @ 500mA |

| Enclosure | Metallic with ABS bezel and polycarbonate front fascia |

| Note : Specifications are subject to change without notice – due to continuous upgradation. | |

Note : Specifications are subject to change without notice – due to continuous upgradation.

.

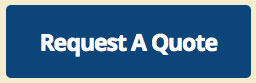

PC BASED INTERFACING SOFTWARE (DAS) :

Libratherm offers customized data logging software to meet various applications. The communication between the data logger and the PC is established using RS232/RS 485 interfacing bus and the data transfer are based on the MODBUS ASCII protocol. The supporting window based software available on the CD is required to be pre loaded onto the computer.

When the PC is connected to the data logger, the data can be on line transferred to the PC where the PC acts as a master and sends queries to the data logger to send the real time data with date, time, channel number and process values. The pc will process these data to store in the tabular as well as the graphical format, which can be viewed on demand as on line or offline data. The software allows user to store other information, such as, Company name, Batch number, process name, as well as certain customized fields. This makes the software user friendly and dedicated to the requirement.

When the PC is not connected to the data logger, the datas can be stored in the built in internal memory or in the external memory card (LIMEM-128) of the data logger. These stored data can be later on dumped on to the PC for direct display of graph and table.

The following screens shows such software features.

VARIOUS CONTROL PANEL USING DATALOG-16

![]()