Microprocessor Based Temperature / Humidity Controller

for Stability Chamber

Product Specification :

Model wise descriptions :

| Model | Description |

| HTC-3003 | Microprocessor based Temperature & %RH PID-On/Off controller (2 inputs and 3 or 4 outputs) with RTC, Printer port, RS-485/RS-232 Serial port and Extra 128KB memory bank. (Simultaneous Display of T and RH) |

| HTC-3000 | Microprocessor based Temperature & %RH PID-On/Off controller (2 inputs and 3 or 4 outputs) with RTC, Printer port, RS-485/RS-232 Serial port and Extra 128KB memory bank. (Scan Display for T and RH) |

Description :

Libratherm offers Microprocessor based Humidity and Temperature Controller Model HTC-3003 and HTC-3000 with input and output suitable for measuring and controlling the T and RH of stability or environmental test chambers. These chambers are mainly used in Pharma, Petroleum, Chemical and Food Industries to test the sample under the desired simulated levels of temperature and humidity.

The controller accepts input from the standard T + RH sensors consisting of (Pt-100) temperature sensor and the capacitive type RH sensor or from T + RH transmitter. (The suitable sensors or transmitters of international brands can also be supplied along with this controller).

In model HTC-3003, the process values and set values are displayed simultaneously in the range of 0.0 to 99.9 oC and 0.0 – 99.90% RH respectively on 4 independent 3 digit 7-segment Red / Green LED displays. The real time is displayed on 4 digit display.

In model HTC-3000, the process values and set values are displayed on the same 4 digit display with 2 digit display for the respective unit. The display will scan at the programmed rate and indicates T and RH alternately. HTC-3000 has only advantage of HTC-3003 is that of temperature can be indicated up to 200.0 oC. The real time is displayed on 6 digit display. Otherwise both the models are similar.

Since these controllers are basically designed for the stability chambers, the accurate control of temperature and humidity is achieved by operating the air heater (for Dry heat) and the boiler heater (for Moisture) in the PID control action. And the compressor (for low temperature) is operated in ON/OFF action with time delay facility. Since the compressors are not required to be kept ON above certain level of temperature, the user selectable mode is provided to program the compressor operation in AUTO, Continuous ON or Continuous OFF mode. To de-humidify the system, an extra ON/OFF output can also be optionally provided. The control outputs are in the form of SSR drivers of (0 – 10) VDC pulse to control the Air heater, boiler heater and compressor and dehumidifier.

In addition, these controllers have many other useful features such as, in-built real time data storage facility, which can be retrieved on demand or can be down loaded on to a computer or on a printer for hard copy via the built in printer port. The storage capacity depends on the logging time. Maximum 480 records can be stored which can be printed in OFF line mode. For larger storage, additional memory card increases the capacity up to 3000 records.

These models also accepts 2 nos. of external potential free contacts to detect the water level of the boiler used for generating the steam or moisture and to monitor the status of the front door of the chamber – through limit switch contacts. The Door operating command can be issued externally from the PC .

The controllers are ready with the serial communication port RS 232 or RS 485 in ASCII modbus format for interfacing to the computer for data logging and storage.

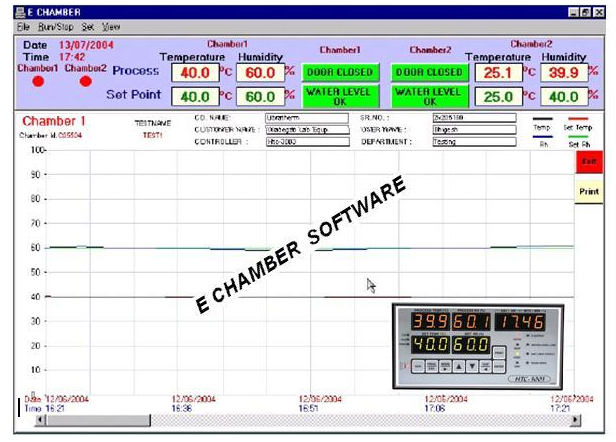

Specially designed window based E-Chamber Software (as per our standard or as per CFR compliance) does the on line data logging and plot the online / offline graph on the PC and also allows user to enter the set points and control parameters through PC and the controller.

(i.e. bi-directional communication).

Features :

• Microprocessor based design.

• Easy front panel keyboard programmable.

• Independent 4 control outputs for Temperature/%RH control.

• Digital input for water level, door switch etc..

• PID or ON/OFF control action for Air heater, Boiler heater and ON/OFF control action for Compressor with programmable time delay.

• Direct dot matrix parallel / Centronics printer output for EPSON printer model LX-300+ or Equivalent.

• RS-485 or RS-232 PC computer interface.

• Standard software or CFR complaint software.

Application :

• Stability / Environmental Test Chambers

• Walk In Chambers

• BOD Incubator etc

Sensors for (T + Rh) Measurement :

Libratherm controllers are designed to accept the T+RH probe or the Transmitter from various models of Rotronic – Swiss. User has the choice to select suitable probe or the transmitter based on the application and the range of measurement. Standard OEM products from Rotronic are available from us to be used with T+RH controller model HTC-3003. A detail of the same is given below in Table 1.

Technical specifications :

| No. of Input | 2 (one each for Temperature (T) and % Relative Humidity (%RH)). |

| Input | T + RH sensor probe or Transmitter Refer Table 1. |

| Range | -40.0 to 60.0 oC or 0.0 to 60.0 oC , 0.0 to 200.0oC and 0.0 to 99.9 %RH. |

| Resolution | 0.1 oC / % |

| Accuracy | Better than ± 0.1% for temperature and ± 2% for RH. (Taking into account the sensor accuracy). |

Display (HTC-3003) |

3 digit 0.5” Red 7-segment LED display for Process Temperature. 3 digit 0.5” Red 7-segment LED display for Process Humidity. 3 digit 0.5” Green 7-segment LED display for Set Temperature. 3 digit 0.5” Green 7-segment LED display for Set Humidity. 4 digit 0.5” Red 7-segment LED display for RTC. |

Display (HTC-3000) |

4 digit 0.5” Red 7-segment LED display for Process Temperature and RH 4 digit 0.5” Red 7-segment LED display for Set Temperature and RH 2 digit 0.5” Red 7-segment LED display for unit ( oC or RH) . 6 digit 0.3” Red 7-segment LED display for RTC. |

| Tuning | Manual tuning of PID values. |

| Control Action | PID or On/Off as required. |

| Open Sensor Indication | Display shows Fault messages and control outputs will be turned OFF. |

| Settings | Retention of PID and set values in the non-volatile memory in the event of power failure. |

| Memory Backup | Retention of PID and set values in the non-volatile memory in the event of power failure. |

| Control Action | PID for Air Heater and Boiler heater. On-Off with programmable hysteresis for Compressor and Dehumidifier. |

| Control Output | For Air Heater, Boiler Heater, Compressor and Dehumidifier in the form of DC pulses 0 to 12 VDC to drive external SSRs. |

| Event Outputs | 2 Extra Relay outputs can be used as High/Low or Day/Night effect. |

| External Input | Potential free contact input for water level & door switch. Water level switch is interlocked with control outputs. |

| Data Logging | Real Time with programmable log time and storage time. |

| Data Storage | 2K memory bank – sufficient to store 480 records. For more storage memory can be expanded up to 128KB. |

Serial / Parallel Interface |

Parallel Centronics port (25 pin D connector) fo 80 column dot-matrix printer (EPSON or Equivalent). Serial port (RS232- 4 wire or RS485 - 2 wire) on modbus ASCII protocol. USB interface can also be optionally provided. |

| Supply | 230VAC or 110 VAC ± 10% (10VA), 50/60Hz. |

| Size | 192 x 96 x 200 mm |

| Panel cut out | 186 x 92 mm +/- 0.5 mm. |

| Enclosure | Metal Powder coated with ABS front bazel and polycarbonate graphics. |

Input Sensor / Transmitter and Range Selection Table:

(Which can be used with above controllers)

| Sensor / Transmitter | A1 (Sensor) | A2 (Transmitter) | A3 (Transmitter) |

| Model | HYGRO CLIP –CP | HYGROTX-3000 | H290 |

| Type | Sensor | Transmitter | Transmitter |

| Make | Rotronic – Swiss make | Libratherm | Rotronic |

| Temp. Sensor | In-built | Hygroclip-CP | In-built |

| Supply | (5-24) VDC | 18-24VDC | (5-24) VDC |

| %Rh O/P | 0 TO 1 VDC | 4-20mA | (4-20) mA DC |

| % Rh Range | 0 to 100%RH | 0 to 100% | 0 to 100% |

| Accuracy | +/- 1.5 %RH @23 oC | +/-1.5% @ 23 oC | +/- 1% RH |

| Temp. O/P | 0 to 1 VDC | 4-20mA | (4-20) mA DC |

| Temperature | -40 to 60 oC | -40 to 60 oC | -40 to 150 oC. |

| Accuracy | +/- 0.5% | +/- 0.5% | +/- 0.5% |

| Std. Cable Length | 2 meter | 1 meter with sensor | 2 meter |

| Transmitter Enclosure | -- | ABS IP 65 | ABS-IP65 |

| Transmitter Size | -- | 85 x 85 x 55 mm. | 120 x 85 x 55 mm. |

| Sensor Size | 15 x 140 mm. | 15 x 140 mm | 15 x 200 mm. |

|

|

|

ECHAMBER Standard Software – designed to interface with our controller HTC-3003, HTC-3000 to control temperature and humidity of the stability chambers. The software allows user to monitor the temp. and humidity values on the screen, user can feed the PID, Set Point and Program values through the computer keyboard, one can view the real time values in graphical format which can be zoomed or scaled as per the requirement. Database can be searched with date and time or other user defined fields. Software can be customized to monitor more than one stability chamber on a single screen, selection options are provided to the user. Software can also be supplied to comply with 21 CFR PART 11 requirements.

![]()